You are a slob reloader if:

- Cigarette hanging off the lips

- Beer in one hand

- Phone in one hand

- Dirty lead stained fingertips

- Food in one hand

- Think that the reloading max charge is “just a suggestion”

- Think any load is wimpy unless it is maxed out

- Think that primer seating flush or lower is “overkill”

- Think you can’t make a mistake because “you been doing this for __ years”

- Don’t understand the need for full length sizing (for first run or auto-loaders)

If you fit any of the above, stop reading now and go play out in the street... and if there is any justice in the world you will only kill yourself and not someone who does not deserve to land on the Darwin awards list.

Unlike some ill informed yuppie “survival” sources I am going to give you the researched and documented information you need to safely and reliably load quality ammunition for long term storage.

Safety is you primary concern and should stay priority at all times, an “anal rententive” reloader is a safe reloader.

Starting with primers.

Primer based slam-fires are not a myth this is a well documented FACT any source that attempts to propose that primers are not all that different and information can be “safely ignored” is giving dangerous advice. Free-floating firing pins in auto-loading firearms can and do cause an accidental “full-auto” condition from time to time. This without a doubt is as dangerous as an “out of battery” detonation. Often the entire magazine will fire without stopping and the panic handling of that out of control firearm is likely to cause an “out of battery” detonation. Again an “out of battery” detonation is known for destroying or severly damaging the firearm and harming nearby people as well as the shooter.

Yes there are real differences in magnum and standard primers (magnum primers have more material and burn longer) and there are thicker metal primer cups used in the “military” primers. Wolf brand primers marked “magnum” rifle primers are actually the thicker cup “military” primers charged as a standard primer. CCI produced “military” primers are the thick cup type and are charged as magnum primers. Use your reloading manual to find the specific use of magnum primers, not all cartridges identified as “magnum” will require a magnum primer. Here is a run down from the reloading manual:

Magnum primers are the appropriate choice for cartridges such as the popular .357 Magnum. Magnum primers work well with large volume cartridge cases, large volumes of powder, and slow burning powders this is also helpful with ball/spherical powders. Use of magnum primers is useful in non-magnum cartridges when extremely cold shooting conditions are encountered. Care should be used with magnum primers as the additional power represented in the primer itself can create overpressure in listed standard loads.

A magnum primer is useful in non-magnum cartridges for specific reasons such as cold weather conditions, but be advised that the loads for this combination must be worked up from the standard 10% drop in powder charge. When magnum primers are substituted for standard primers you can expect two grains of powder power value with rifle and .5 grain of power value with pistol loads - or greater, you must be careful and this is your responsibility to double check with your loading manuals.

Primer brands also have characteristics that make them more or less desirable for your particular uses. Federal primers are noted for consistency and favored by many accuracy minded shooters but are also slightly larger than standard with a sharp edge making them difficult to push into the primer pocket.

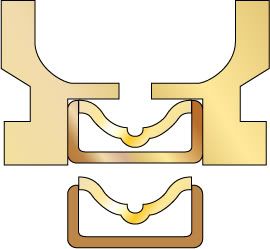

Always seat primers slightly deeper than flush/slightly recessed and slightly flattened (but not crushed) a slight compression of the charge pellet agianst the anvil fully into the primer pocket will be best. Often factory primers have a slightly extended anvil base as illustrated in the cross-section below, seating this into the pocket as the upper illustration will compress the primer charge slightly and should allow the primer to seat slightly below flush.

Consider adding a primer pocket cleaning brush and primer pocket uniforming cutter as they clean and uniform the inside well of the primer pocket this will aid in seating as well as remove any contaminants that could cause corrosion (you can forego the cleaning brush if you are using the chemical brass cleaning methods).

It is not uncommon to find primer pocket “crud” that will prevent the primer from seating fully into the pocket a primer pocket brush and a primer pocket cutter/uniformer is almost required when using the Federal large rifle primers.

Shiny, like new primer pocket ready for a new primer.

I do not paint on a sealant to the finished primer, conditions in the dry western states do not dictate that procedure, it may be useful in some rare wet conditions, but I have never had water contamination in any of my non sealed cartridges even in the wet swampy conditions of the gulf coast. It is possibly the most wasteful additional step suggested out in the "internet wild" that has little to no justification. If you don’t expect to have your ammo under fifteen feet of water for three months the primer sealant will only prove to be a problem when it heats and comes off the casing and fouls your bolt face.

One additional warning, some rifles like the HK SL6 and 7 and its brothers the 770 and 630 have extremely violent return and will slam the bolt face hard enough to deform some cases and cause them to fire because the brass in the primer pocket will constrict and ignite the primer pellet charge. Choose and test your brass and primers for reloading carefully.

The cartridge case.

Commonly you will find spent aluminum, brass, and steel cases at the range, contrary to common (and often willfully ignorant) internet drivel steel cases are reloadable and safe to use for handloading (with a possible shorter life) the steel cases are prone to rust formation and therefore best used for “make and shoot” use.

I am not going to go into the pain involved with berdan primed cases or the fact that aluminum cases are dangerous as we have more important issues to review, simply berdan is relaodable but takes aditional steps and time and the primers are not commonly available, aluminum cases are best recycled to avoid problems (try youtube and google for more about berdan primer reloading).

For our basic needs for long term storage brass cases are the most reasonable choice, it is available, easy to work with, and resistant somewhat to corrosion. Brass has its own special types of corrosion, take a look at the below photos, note how brass (and copper) corrosion can look surprisingly like mould on bread.

If you store your ammunition with the above corrosion evident, the storage time of that ammunition will be much, much shorter, the corrosion only gets worse.

The above two photographs show the worst type of corrosion on your brass cases, this corrosion is destructive, the brown/grey uniform corrosion (also known as a brown patina) is benign and can actually protect the bras from additional corrosion. The creeping black, fuzzy light green/grey, and red colored corrosion as you see above is quite destructive and sadly “grows” so once started, severe methods are needed to remove and stop the corrosion process. Destructive corrosion must be removed. Note the use of gloves to prevent contamination from oily fingerprints.

The first order of business is to prepare the brass cases for reloading, I prefer to clean the brass to like-new shiny condition and handle with gloves. My current method is to use a vibrating abrasive but the newer stainless steel media with a wet acid process or the sonic chemical cleaning either may prove to be my next method of cleaning brass cases. Both methods give a brighter and cleaner finish to the brass than the vibratory cleaner with walnut hulls chips. The wet chemical methods do clean the inside walls of the case and the primer pocket, cleaned to a mirror finish no less, saving the step of cleaning primer pockets individually and no annoying packed walnut hulls or bits stuck in the primer hole.

For longevity in storage, cleaning the brass may be the most important step. All of my range scrounged brass is first washed in hot top water and dish soap, I have a screw-on lid container and shake vigorously then place in a colander drain and then repeat without soap until the dirt and contaminates are gone. Set out in the sun and dry and then its time to size and de-cap the brass and then clean to shiny-new.

Case preperation often requires trimming the brass to the correct length, I first size all of the brass in batches and then sort them using the callipers to sort too long from the in-spec brass and trim the too long cases. The correct length of the typical rifle case for example, can dictate if the round will load into the rifle’s chamber or end-up jammed protruding out of battery.

A typical case trimming lathe, notice that a portable hand drill is connected to speed up the trimming of cases.

Component storage.

Cool, dry, dark - the standard for all long term storage, I will add to this, be sure and isolate the active components (primer and powder) from any solvents and fumes, finished ammunition can benefit from this simple rule also, but the active components are very susceptible to damage by fumes, solvents, and oils.

The bullet

A recent question I started to calculate was the type of projectile I wanted in storage, I have a considerable amount of military surplus non-corrosive ammunition with full-metal-jacketed bullets probably the most pathetic choice for self defense. Lets be honest how many “bad guys” will be out there and wearing projectile resistant body armor? Instead of drilling a very small consistent hole in a deer you need to eat to survive - and then watching it bound into the distance never to be seen again -would you not prefer to have a premium preforming bullet drop it within 100 yards?

I was given the task of removing some dangerous wild dogs years ago and I stupidly loaded my self-loading .308 with surplus FMJ rounds and every canine I shot center chest and every one ran-off - in one case we found one over a full mile away from where he was shot! I for one would want to drop a dangerous wild dog on the spot. FMJ bullets are just not capable of the shock and consistent terminal performance of a premium bullet. What can we expect - "pointed ogival spitzer tip shape have a tendency to fragment on impact with soft tissue, harder organs, bone or the clothing and/or equipment worn by the individual soldier” but this effect aided by the sections and cannelure (yes the bullets sometimes fold in half and break at the cannelure).

I have seen it proposed that softer tips can cause malfunctions in some rifles and that the deformation of the tip will make a “flyer,” what is interesting is that you can find on-line an several test studies of bullet performance with deformed tips from several rifles including magazine feed, and will find that the accuracy difference is actually less than the diameter of the bullets at 100, 200 and 300 yards. Bullet deformation that will impact the accuracy the most is damage to the base of the bullet look over a few varmint and benchrest groups for more information (or "The Bullets Flight" by Franklin Mann). Simply put the greatest two bullet related issues for accuracy are the base and the exit of the bullet from the barrel. Giving up premium bullets for FMJ for the deformation issue is just following ignorant wives tails - if you have a rifle that will not feed reliably with premium bullets - trade that pig out on a rifle that actually works! Anyone proposing that slight tip (meplat) deformation is equal to massive loss in accuracy has just not done any serious research (a massive problem with many delusional and ignorant yuppie survivalists).

Premium bullets are available in bulk for prices not that much higher than bulk FMJ when you look at the possible usefulness of the round loaded with a premium bullet (at the time of writing this Graf and Sons has .308 150 gr. FMJ for $20.59 per 100 and Lead Tip 150 gr. for $

Premium 9mm (.355) 121 gr. lead tip hollow point bullets ready to load.

Loading the final cartridge.

I always seat to standard lengths that fit all the loading devices (clips, magazines, and tubes) for that round and crimp using Lee’s factory crimp dies. This is a choice based on the possible need to use “anything” in the collection in “any” rifle and from my testing and the testing of others the Lee factory crimp dies actually improve accuracy for standard use loads. I do have quite a bit of storage ammunition that is made specifically for a longer range scoped heavy barrel .308, but all of the ammo will work in all of the .308 rifles in a pinch.

There is from time to time the suggestion that “tar sealed” bullets are premium for storage, not only is the procedure difficult and time consuming but the results are best described as “dirty as a five dollar crack whore.” I see no reason to seal the bullets myself, I use a crimp die that I think accomplishes this well, but if I were to take the time - the method of applying a thin layer of melted paraffin wax to the inside with a q-tip before pouring the powder and seating the bullet I think has some merit. Glue, tar, paint, and other sealing compounds are all future contaminates.

Long term storage

Back in the 1980s a strange little book came to my attention, I remember that he suggested placing your ammo into military ammunition boxes and then covering the boxes with fiberglass and resin (a hot procedure due to chemical heating) for storage underground. Can you imagine the effort it would take to open that box? Hey guys wait with the raping and looting I need to get my ammo out! I have to chuckle about the strange ideas we see every day.

I prefer to also box all the ammunition into containers like the Midway or Top Brass cardboard boxes (similar to factory boxes) or into the plastic storage boxes like the Berry’s or case-guard. All of the ammunition is stored in three ways, in air sealed tool lockers, in vacuum packed “grab bags” and sealed PVC pipe for burial catches.

Now we do want the optimum conditions, again they are cool, dry, dark and one addition, clean. I do prefer the typical blank cardboard box as it is non-reactive and is not tightly air sealed, I have some corrosion on some green soft plastic “battle packs” of Portuguese ammunition that clearly they sealed with some moisture inside the “battle packs” obviously moisture is a major factor in brass corrosion and this has allowed some corrosion to damage the brass in the packs obviously a desiccant packet would have helped.

I have several PVC storage containers, what bothers me most about this particular method is not that it does not work - in fact it works very well - it is the fact that it is difficult to open and takes time even with the correct tools. I keep thinking of a quote but I do not remember the source “by the time you put your guns into the ground it was long past the time to start using them!'